|

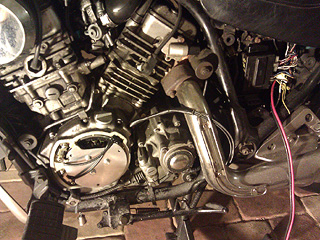

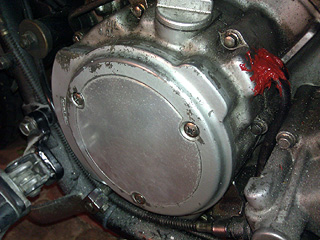

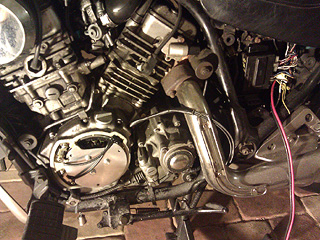

| This mod consists of cutting a large hole in the side of the engine to gain access to the stator. Then a mounting plate is added to support the stator after replacement. |

|

|

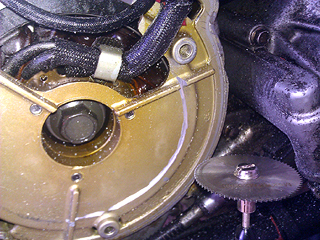

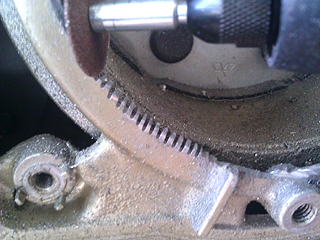

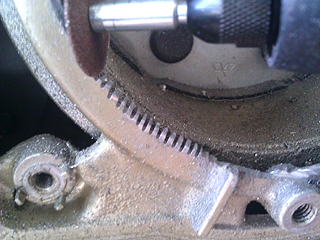

| I used a toothed saw to make an initial cut about 1/3rd of the depth. This type if saw creates a lot of metal shavings which I did not want to get into the engine which is why I didn't cut completely through with it. |

|

|

| The rest of the cutting used several standard dremel cutting wheels. These create more of a dust which is less harmful if it gets inside the bike. |

|

|

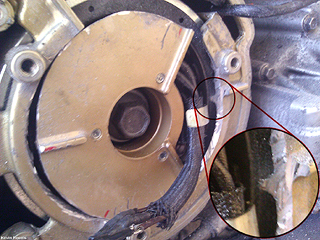

| Here we see the initial cut completed and the left side cut completely through. |

|

|

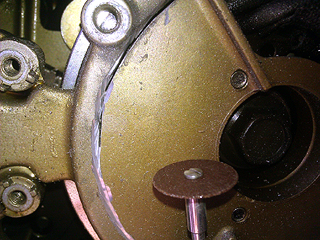

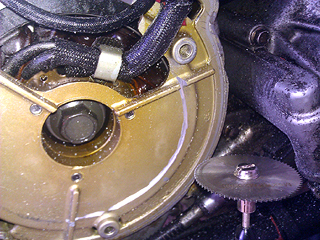

| There are a few thick supports which can snag on the stator during removal. By rotating the cut out part I was able to gain better access to these and cut them down. |

|

|

| The hole at this point wasn't quite big enough in some places. I was able to remove the already-bad stator but I wanted clearance for the new part. This shows the method I used to easily enlarge the problem areas. I made a bunch of cuts, then from a side angle cut those bits off. |

|

|

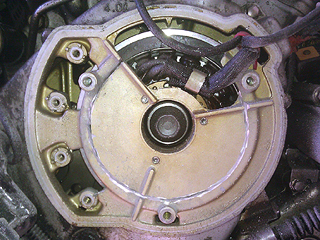

| Finally I smoothed out the edges and cleaned things up a bit. At all times I kept the direction of the tool moving away from the bike to minimize the amount of debris entering the engine. Obviously, an oil/filter change will be required after a few miles. |

|

|

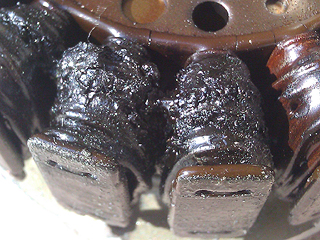

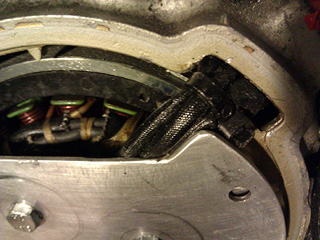

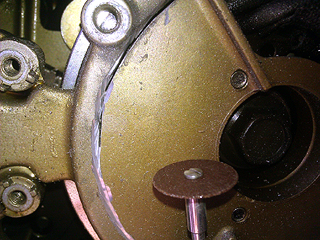

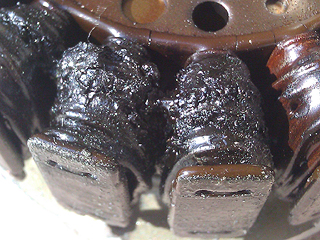

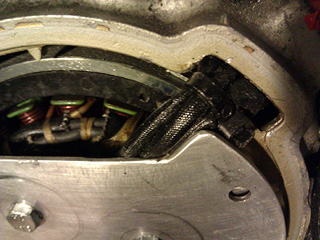

| Here is the old burnt out stator. |

|

|

| Close up of the damaged area. This was causing all kinds of problems with the charging system. |

|

|

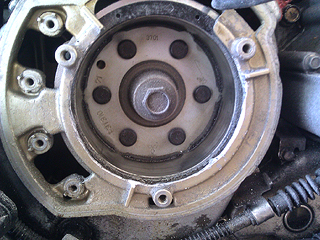

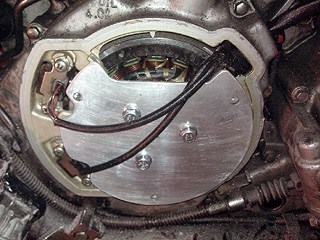

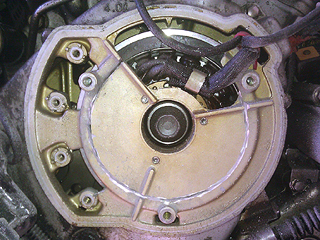

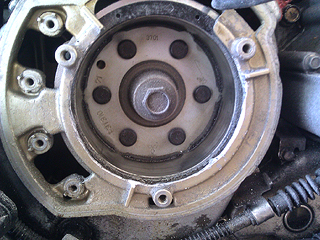

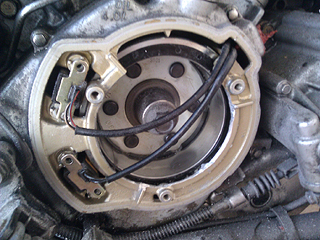

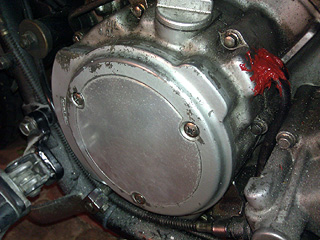

| Here's one more shot before the new stator and mounting plate go on. |

|

|

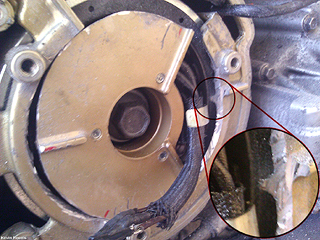

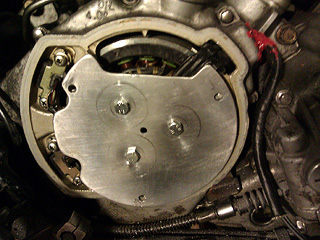

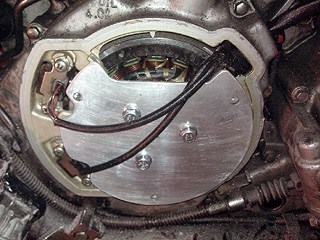

| A wide shot of the mounting plate. This was crafted by Rags from vn750.com. Due to the very strict tolerances required, I decided to buy the plate from someone who's been making them for awhile. |

|

|

| A closeup of the plate. Initially I had the timing wires going over the plate as you can see here. This leaves little room for the cover to go on. |

|

|

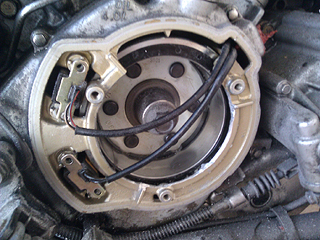

| To make room for the wires and bolt heads it is necessary to grind down parts of the cover. Even after doing this, the wires still prevented the cover from sealing firmly around as it should. |

|

|

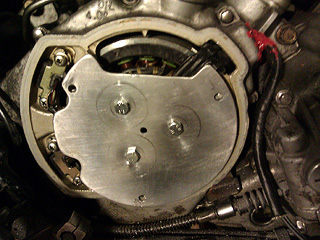

| My solution was to re-route the wires under the plate. There happens to be gaps between the spacer which the stator is mounted to and the plate. The wires are passing through these gaps. |

|

|

|

|

| Side angle. Notice I also switched out the bolts for ones with less bulky heads. |

|

|

| Here it is with the cover on. |

|

|

|